ADVANCED CATHODE CANS

Cathode New Design

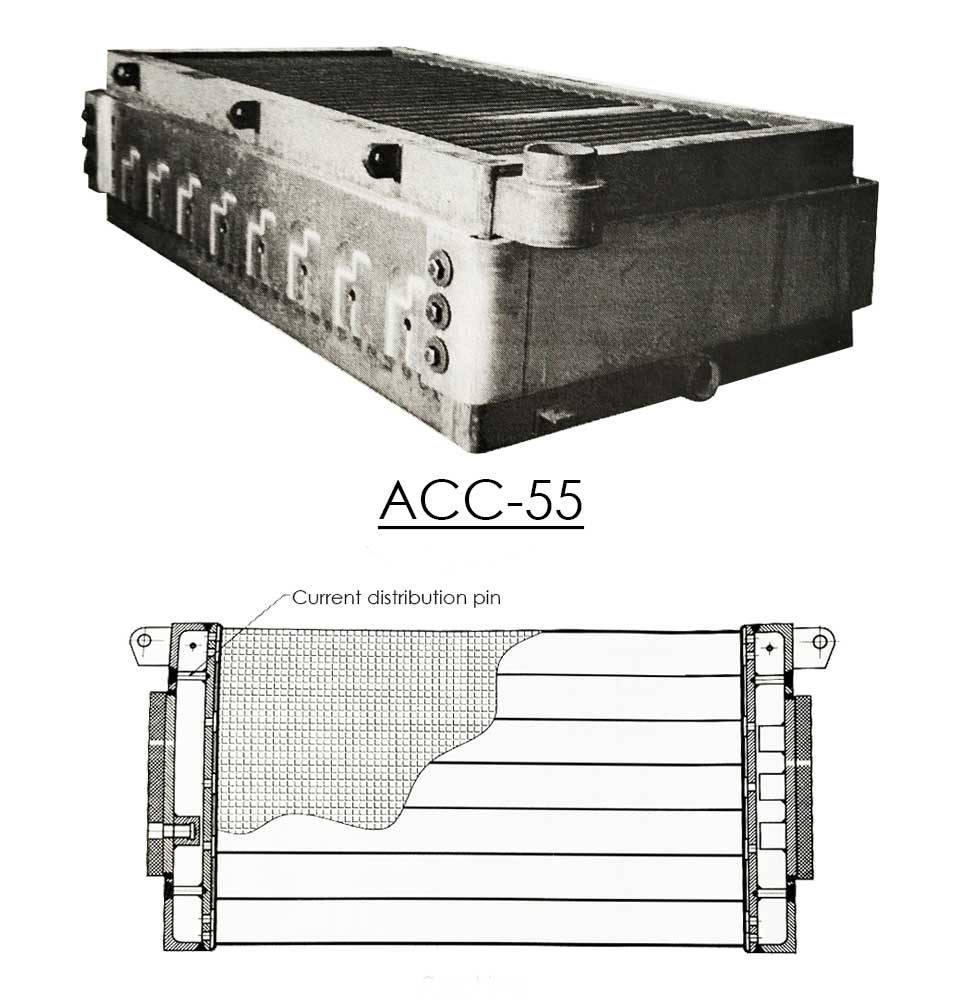

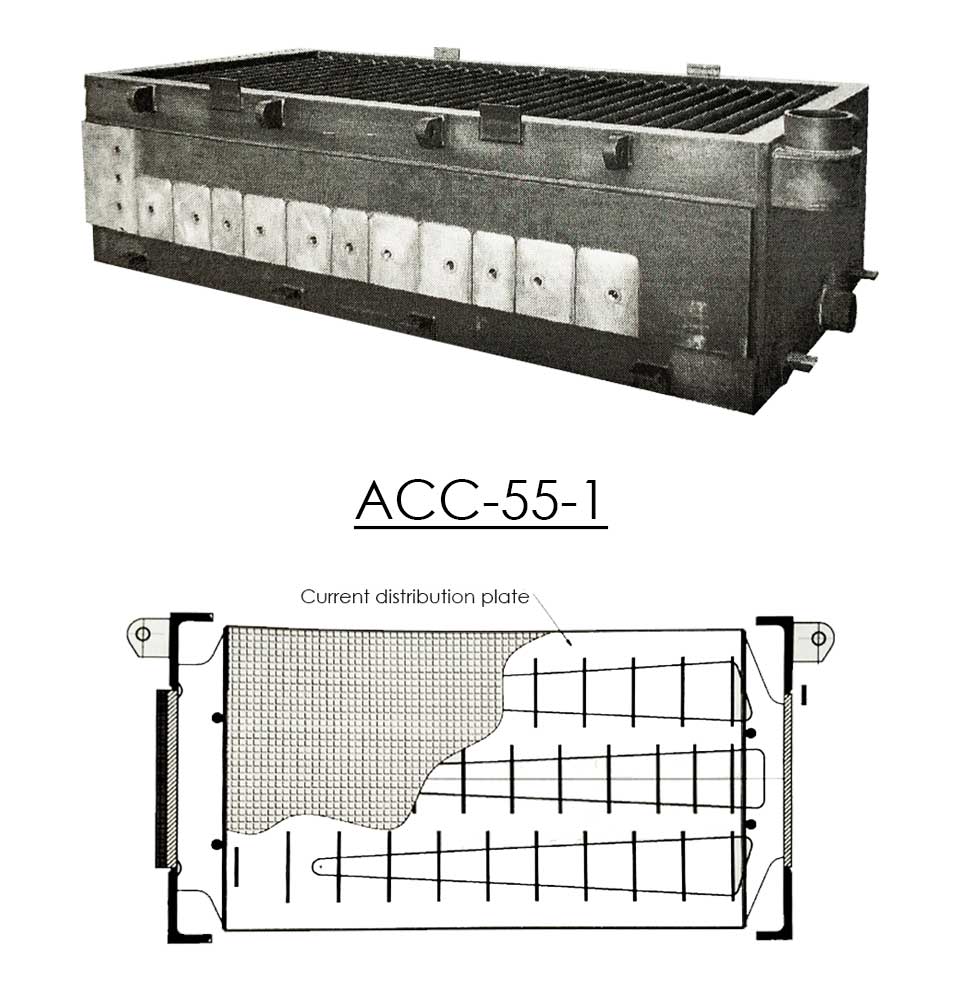

Can-Tech has developed and constructed new cells ACC 29-1 and ACC 55-1 with the following properties:

- Only 1 Copper/Steel plate.

- The Copper/Steel plates are full explosion bonded which guarantees a perfect fixation.

- An innercathode consisting of full tube screens and 2 half tube screens.

- Each full tube screen is made of a thick steel plate (current distribution plate) placed in the center of the full tube and 2 tube screens made of Jonge Poerink Heavy Duty screen.

- The current distribution plate has long slot holes for excellent (vacuum-)depositioning of diaphragm material.

- Steel spacer strips are welded on the current distribution plate to create a distance between the current distribution plate and the woven tube screen.

- 2 tube screens are welded with spot welds on the spacer strips and with welds over the full length on the top and the bottom to cach other and the current distribution plate.

- The welds on the top and bottom have a max. width of 7 mm.

- The half tubes consists of a current distribution plate and on one side spacer strips and tube Screen.

- The current distribution plate is welded directly behind the copper/steel plate. For all internal connections thick steel is used and not a combination with copper (it prevents copper-iron corrosion).

Advantages:

- Homogeneous temperature distribution, inside and outside the cathode.

- Excellent current distribution.

- Low electrical resistance

- Low voltage drop

- Very stable positioned wire screen. It guarantees homogeneous distance between anode and cathode wire, even after many years.

- The electrical cell resistance will be constant, almost during the whole lifetime of the cathode.

- Less corrosion through material choice

- Longer lifetime of cathodes, which can reach up to twelve years in the field

- No copper pollution in cell liquor

Safety aspects

The internal spacer strips are constructed vertically to realize hydrogen discharge to the header with minimal resistance. This results in less pressure fluctuations in the cathode compartment.

Advantages:

- Less chance on short-circuit and cell damage.

- Longer and safer diaphragm lifetime.

- Less hydrogen in chlorine gas, and therefore less chances on hydrogen explosions.

The Advanced Cathode Cans (ACC), developed by Can-Tech for different types of cathodes show following improvements compared with the conventional cathodes:

- Heavy Duty Screen

- Welding Quality

- Optimal internal current distribution connections

- Complete cathode stress relief

- Significant Energy Savings

An optimal electrolysis process with maximum energy savings depends too from:

- Diaphragm quality

- Anode configuration (a.o. expandable anodes)

- Brine quality

- Process circumstances

- Current efficiency

Diaphragm uniformity and strength is essential for high current efficiency and long life-time of the electrolysis cells. In combination with expandable titanium-rutherium anodes it results in long and low energy consumption.

Polluted brine causes plugged diaphragms and results in bad current efficiency and short lifetime. Besides high salt concentration in brine is beneficial for higher current efficiency.

The following process circumstances influence the cell performance:

- Stability of current density

- Number of electrolysis stops and starts

- Presence of cathode protection during electrolysis stops

- Conversion of salt in sodium hydroxide (NaOH concentration)

- Cell temperature

- Anolyte pH during electrolysis process and stops